At Feiyuan Storage, quality control is not just a buzzword.We have a dedicated team of quality control experts,These experts have the experience and expertise to accurately identify and resolve product quality issues.From the smallest sample to the largest finished product, every step of the production process is rigorously inspected.Feiyuan storage comprehensive and rigorous quality control system ensures that the safety and quality of its products meet the high standards of the industry.

Samples are scrutinized and tested prior to large-scale production to ensure the quality and accuracy of new items.This is especially important for highly customized products, helping to identify potential problems and take corrective action.

To ensure that raw materials are sourced from reliable suppliers and meet the stringent dimensional and quality requirements of Feiyuan storage.The team of inspectors scrutinizes each batch of raw material to ensure that it meets the standards.

During the production process, each component is inspected to ensure quality assurance, dimensional consistency and proper fit.

Detailed measurements of dimensions, angles and weld strength of semi-finished products are carried out to detect product defects at an early stage and take corrective action.This step helps to improve productivity and the quality of the next stage of the batch.

After the product has been manufactured, a rigorous finished product inspection is carried out, which includes checks on dimensions, load capacity, welding conditions, surface finish and flexibility of disassembly/assembly.This helps to ensure that products meet the strictest safety standards and fulfil customer expectations.

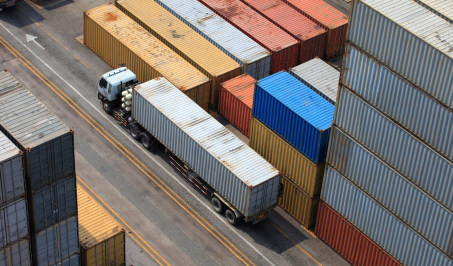

During the loading process, the quantity of the product and the condition of the packaging are carefully checked to ensure that the product can be transported safely.These include checking the packaging is sealed and the method of packaging specifications.

A comprehensive assessment of the structural stability and locking mechanisms of containers to ensure the safety of the goods being transported. Meanwhile, check the quantity and placement of products in the container to minimize the risk of breakage and improve the utilization of space